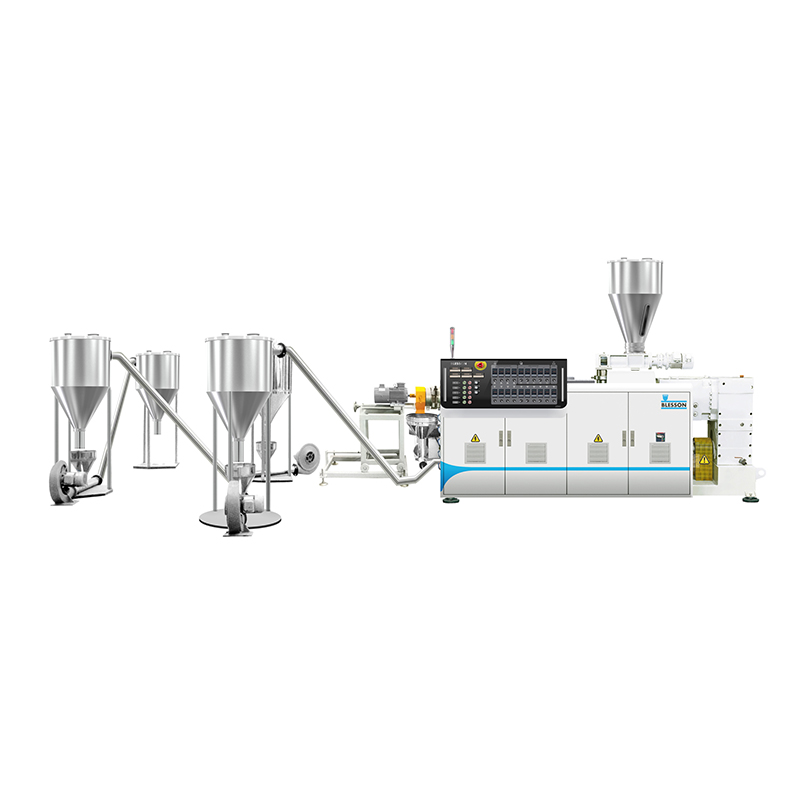

Pelletisearjende line fan hege kwaliteit fan plestik

Wichtichste technyske funksjes

1. De produksjeline bestiet út in extruder, pelletisearjende matrijs, granulator en koelapparaat, dat ienfâldich strukturearre en handich te betsjinjen is.

2. Konyske twilling-skroef-ekstruder mei unyk skroefûntwerp, hege útfier en goed plastifisearjend effekt.

3. Unik ûntwerp foar in better foarmjouwingseffekt.

4. De granulator snijt evenredich, mei in beskermjende omslach om feilige operaasje te garandearjen.

5. De granulaasjeluchttank bestiet út twa koeltanks en ien opslachluchttank, dy't handich en effisjint is foar it sammeljen.

Modellist

| Linemodel | Snijtype | EkstrudearjerModel | Maks.Útfier(kg/oere) | Totale ynstallaasjekrêft(kW) |

| BLZ-65PVC(I) | hjitte snij | BLE65-132G | 450 | 90 |

| BLZ-80PVC(I) | hjitte snij | BLE80-156 | 450 | 120 |

| BLZ-92PVC | hjitte snij | BLE92-188 | 850 | 200 |

| BLZ-95PVC | hjitte snij | BLE95-191 | 1050 | 220 |

| BLZ-130PVC(I) | hjitte snij | BLP130-26 | 1100 | 230 |

| BLZ-55PVC | hjitte snij | BLE55-110 | 180 | 76 |

| BLZ-65PVC(II) | hjitte snij | BLE65-132 | 300 | 90 |

| BLZ-65 PE/PPR | kâld snijwurk op 'e kookplaat | BLD65-34 | 150 | 120 |

| BLZ-65 PE/PP | wetterring hjit snije | BLE65-132 | 150 | 120 |

| BLZ-75PET | kâld snijwurk op 'e kookplaat | BLP75-40 | 350 | 190 |

| BLZ-80PE/PPR(I) | kâld snijwurk op 'e kookplaat | BLD80-34 | 350 | 205 |

| BLZ-80PE/PPR(II) | kâld snijwurk op 'e kookplaat | BLD80-34 | 350 | 180 |

| BLZ-80PVC(II) | hjitte snij | BLE80-156 | 450 | 170 |

| BLZ-80PVC(III) | hjitte snij | BLE80-156 | 450 | 170 |

| BLZ-80PVC(IIII) | hjitte snij | BLE80-156 | 450 | 170 |

| BLZ-92PVC(II) | hjitte snij | BLE92-188 | 850 | 215 |

| BLZ-92PVC(III) | hjitte snij | BLE92-188 | 850 | 205 |

| BLZ-95PET | kâld snijwurk op 'e kookplaat | BLP95-40 | 650 | 340 |

| BLZ-130PVC(II) | hjitte snij | BLP130-26 | 1100 | 240 |

| BLZ-130PVC(III) | hjitte snij | BLP130-26 | 1100 | 240 |

| BLZ-150PE | kâld snijwurk op 'e kookplaat | BLD150-24 | 280 | 340 |

Lit jo berjocht achter

Skriuw jo berjocht hjir en stjoer it nei ús